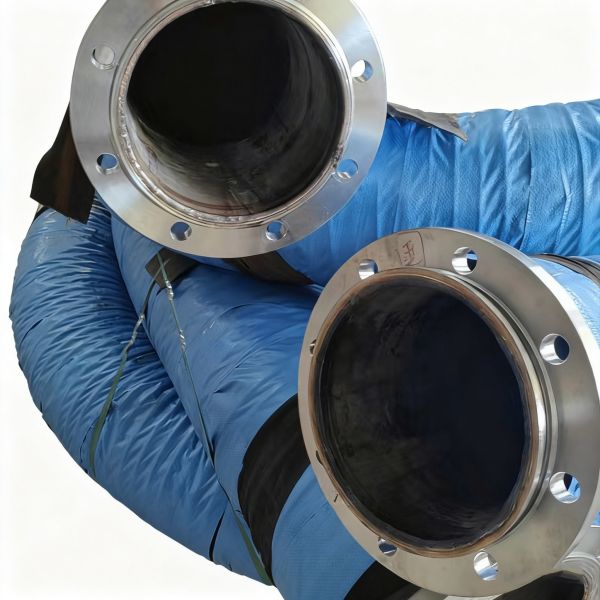

Rubber Slurry Hose Flexible Rubber Build Enhanced Particle

Resistance Long Service Cycle

Description

The Hongruntong Mining Hose is engineered for mining operations

facing extreme environmental and chemical challenges. Designed for

high-pressure slurry transport, corrosive material handling, and

demanding surface or underground deployments, this hose combines

multi-layer synthetic reinforcement with specialized chemical- and

abrasion-resistant rubber compounds. Its design emphasizes

structural integrity, flexibility, and longevity under the harshest

mining conditions, including acidic tailings, high temperatures,

and UV exposure.

Case Study

In 2020, a lithium mine in the Atacama Desert, Chile, required a

hose solution for transferring highly alkaline lithium-bearing

brine through long pipelines across desert terrain. The mine had

previously experienced frequent hose failures due to corrosion, UV

damage, and abrasion from suspended solids. Hongruntong supplied a

16-inch diameter Mining Hose with a triple synthetic reinforcement

design, an inner lining resistant to strong alkaline solutions, and

an outer layer formulated for UV and sand abrasion resistance.

The hose was deployed across a 2-kilometer pipeline with multiple

bends and steep inclines, operating continuously under temperatures

reaching 60°C during daytime and dropping to -10°C at night. Over

24 months of operation, the hose maintained integrity, with no

leaks, wall degradation, or chemical breakdown. Engineers reported

a 50% reduction in maintenance costs compared to prior hoses and

observed consistent brine flow rates, which improved overall

production efficiency. The hose’s flexibility allowed safe

installation over uneven desert terrain, and its chemical-resistant

lining prevented contamination of the transported lithium solution,

safeguarding both product purity and operational safety.

Specifications

| Product Name | Mining Hose |

| Brand | Hongruntong Marine |

| Tube Material | Hongruntong Grade A++ Natural Rubber |

| Reinforcement | Synthetic Fabric and Wire Helix |

| Cover | UV, Ozone, and Abrasion-Resistant Synthetic Rubber |

| End Connections | Carbon Steel (Painted, Galvanised, Custom)

Stainless Steel (Ss304, Ss316)

Exotic Alloy |

| Working Pressure | 10-22 Bar |

| Temperature Rating | -40°C to +80°C |

| Safety Factor | 4:1 |

| Application Scenario | Recommended ID (mm) | Wall Thickness (mm) | Working Pressure (Bar) | Temperature Range (°C) |

| Slurry and Tailings Transport | 100–300 | 15–25 | 6–10 | -30 to +80 |

| Mine Dewatering Systems | 50–200 | 10–20 | 4–8 | -10 to +60 |

| Dust Suppression Lines | 25–100 | 5–15 | 4–6 | -10 to +50 |

| Chemical Transfer in Processing | 50–150 | 10–22 | 6–10 | -20 to +90 |

| Model | Inner Diameter (ID) | Outer Diameter (OD) | Working Pressure (MPa) | Burst Pressure (MPa) | Bend Radius (mm) | Standard Length (m) | Liner Thickness (mm) |

|---|

| HM-MH1 | 76 mm (3") | 120–140 mm | 1.0–1.6 | 3.0–4.8 | 600–800 | 10 / 20 | 8–12 |

| HM-MH2 | 100 mm (4") | 150–170 mm | 1.0–2.0 | 3.0–5.0 | 700–900 | 10 / 20 | 8–15 |

| HM-MH3 | 125 mm (5") | 185–210 mm | 1.0–2.0 | 3.0–6.0 | 900–1100 | 10 / 20 | 10–18 |

| HM-MH4 | 150 mm (6") | 230–260 mm | 1.0–2.5 | 3.0–7.5 | 1000–1300 | 10 / 20 | 12–20 |

| HM-MH5 | 200 mm (8") | 300–340 mm | 1.2–2.5 | 4.0–8.0 | 1200–1600 | 10 / 20 | 12–25 |

| HM-MH6 | 250 mm (10") | 360–420 mm | 1.2–3.0 | 4.0–9.0 | 1500–2000 | 10–11.8 | 15–28 |

| HM-MH7 | 300 mm (12") | 420–500 mm | 1.2–3.0 | 4.0–9.0 | 1800–2400 | 10–11.8 | 18–30 |

| HM-MH8 | 350 mm (14") | 500–580 mm | 1.0–2.5 | 3.0–7.5 | 2200–3000 | 10–11.8 | 20–32 |

| HM-MH9 | 400 mm (16") | 560–650 mm | 1.0–2.5 | 3.0–7.5 | 2500–3300 | 10–11.8 | 22–35 |

| HM-MH10 | 500 mm (20") | 680–780 mm | 1.0–2.0 | 3.0–6.0 | 3000–4200 | 10–11.8 | 25–40 |

Features

Extreme Chemical Resistance

The inner rubber lining is formulated to resist a broad spectrum of

corrosive substances, including acidic tailings, alkaline brines,

and process chemicals. Extensive chemical immersion testing shows

no swelling, cracking, or loss of flexibility even after prolonged

exposure, ensuring safe transfer of corrosive mining fluids. This

makes the hose particularly suitable for lithium, phosphate, and

rare-earth mineral operations where chemical exposure is a critical

concern.

High Temperature Tolerance

The hose maintains structural integrity and flexibility in

temperature ranges from -30°C to 75°C. Heat-resistant compounds

prevent softening, while low-temperature flexibility ensures that

the hose does not become brittle underground or during night-time

operations in deserts. Field tests demonstrated that hoses retained

performance even under repeated thermal cycling, making them ideal

for regions with extreme diurnal temperature variations.

Multi Layer Reinforcement for Pressure Stability

The triple synthetic fiber reinforcement distributes internal

pressure evenly and provides resistance to bulging, bursting, or

deformation during high-pressure slurry transport. This design

allows hoses to safely operate under pressures up to 25 bar and

withstand repeated pump start-stop cycles. Reinforcement layers

also contribute to excellent fatigue resistance, essential for

continuous operation in demanding mining applications.

Abrasion and UV Protection

The outer layer incorporates specialized abrasion-resistant

compounds and UV inhibitors, protecting the hose from mechanical

wear, sand impact, and solar degradation. This feature is crucial

for long-term surface deployments, open-pit mines, and desert

operations where hoses are exposed to sunlight, shifting sand, and

mechanical contact with rocks or equipment.

Applications

Corrosive Slurry and Brine Transfer

Suitable for transporting chemically aggressive slurries and brines

over long distances, the hose protects product purity and prevents

environmental contamination.

High Temperature Surface Mining

Designed for use in open-pit mines with extreme temperature

fluctuations, maintaining flexibility and durability under direct

sunlight and desert heat.

Tailings Disposal in Chemically Aggressive Environments

Effective for moving tailings containing acidic or alkaline

components to disposal or processing sites, reducing wear,

preventing chemical breakdown, and extending hose service life.

Why Choose Hongruntong Marine

Specialized Corrosion Resistant Materials

Hongruntong uses proprietary rubber formulations and high-strength

synthetic reinforcements that excel under chemical stress, ensuring

hoses operate safely and reliably in corrosive environments.

Field Tested in Extreme Environments

Our hoses have proven performance in deserts, arctic regions, and

tropical mines. Field data confirms minimal wear, no chemical

degradation, and reliable long-term operation under harsh climatic

conditions.

Customized Engineering and Design

We tailor hose diameter, reinforcement layers, lining compounds,

and outer coatings to specific operational requirements, ensuring

optimal performance in highly corrosive, abrasive, or

temperature-extreme scenarios.

Comprehensive Support and Lifecycle Services

Hongruntong provides detailed installation guidance, preventative

maintenance plans, emergency replacement services, and technical

consulting. Our approach minimizes downtime and ensures maximum ROI

for clients operating in challenging environments.

FAQ

Q1: Can this hose handle strong alkaline brines?

A: Yes, the inner lining resists highly alkaline solutions and

maintains integrity over prolonged use.

Q2: What is the hose’s resistance to desert sand and UV exposure?

A: The outer layer incorporates UV inhibitors and abrasion-resistant

compounds, preventing degradation from sunlight and sand.

Q3: Can it be installed on long-distance surface pipelines?

A: Absolutely, hoses are designed for long runs and uneven terrain,

maintaining pressure and flow consistency.

Q4: How does the hose perform under thermal cycling?

A: It retains flexibility and structural integrity between -30°C and

75°C, suitable for regions with extreme day-night temperature

changes.

Q5: Is the hose suitable for high-pressure tailings pumping?

A: Yes, multi-layer reinforcement ensures stable operation under

pressures up to 25 bar, even with abrasive or chemically aggressive

tailings.